The 2025 NMLRA wheellock building class was a success!

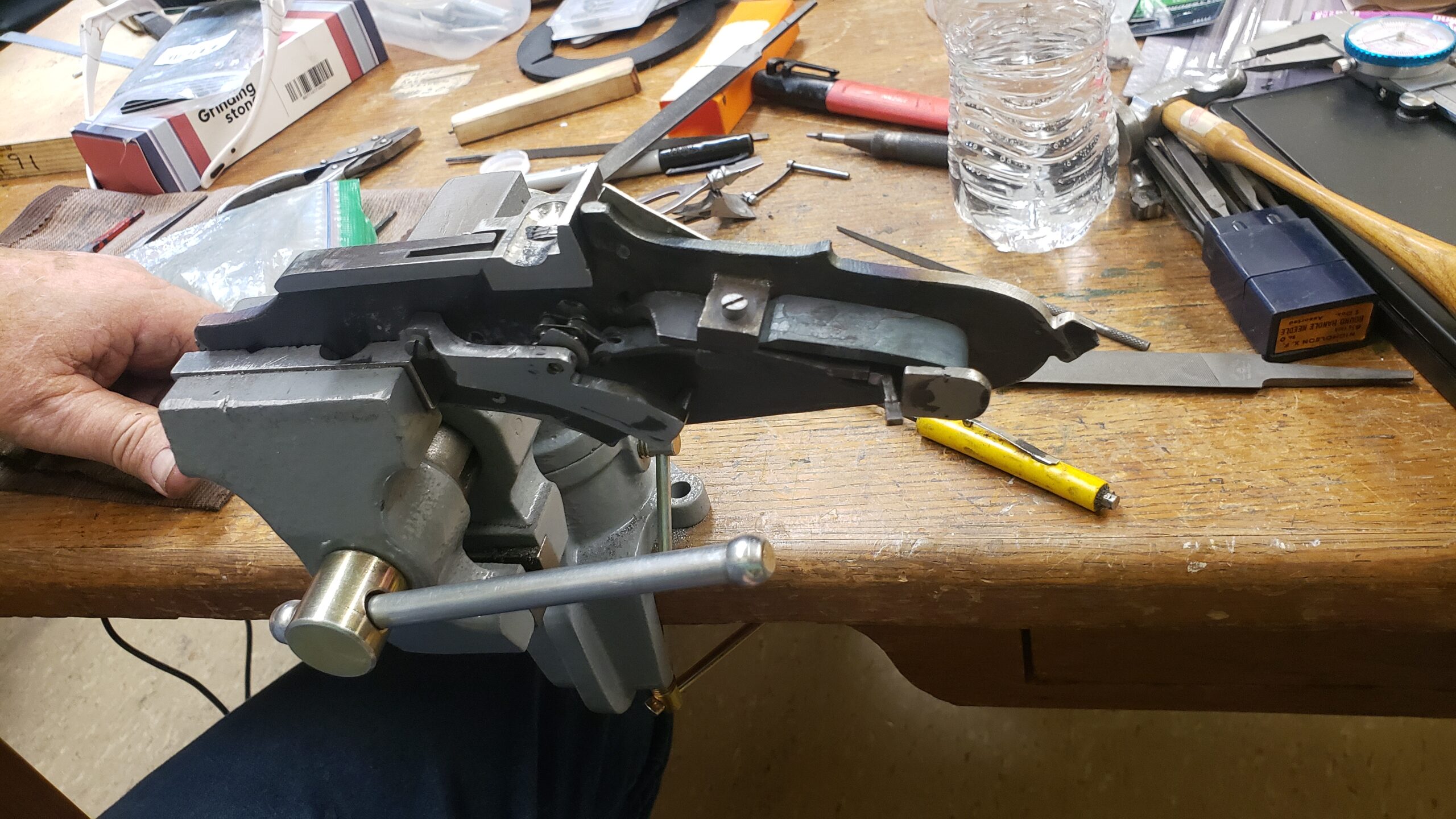

The 9 day class was barely enough time to get a functioning wheellock mechanism built. There were some issues with the castings from the foundry. (See the write up here.) The material was not a consistent density and also contained hardened particles embedded. We broke a few taps also. Most of the springs that were hardened & tempered in a temperature controlled furnace repeatedly failed. There were voids in the castings. Pin holes and channels.

We persevered!

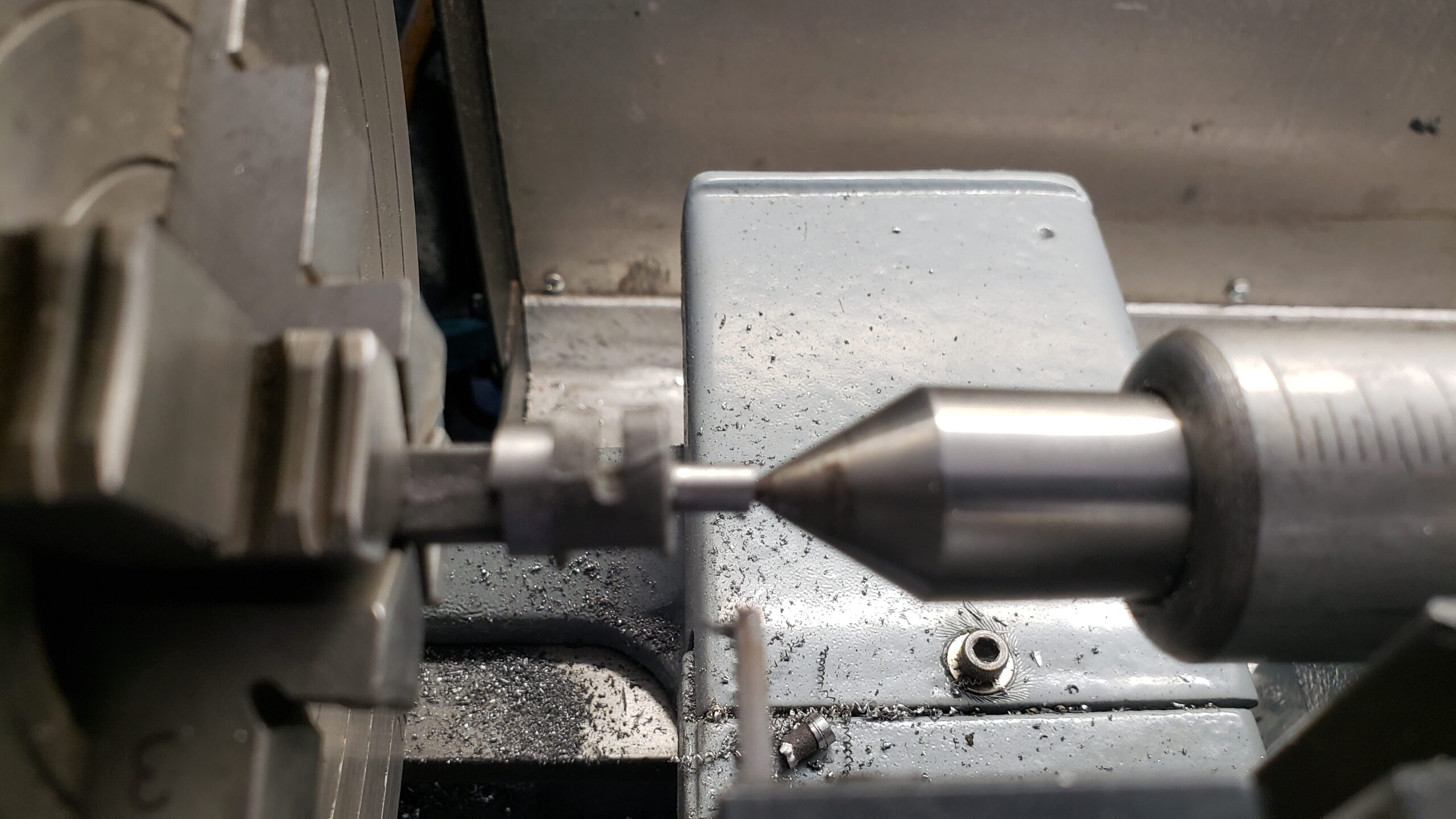

Ensuring that the axel is true to center is critical. Machining the parts before the class allows for faster building of the lock. All castings available from originals, TRS and others, are not true to the intended geometry. The parts were hand made and fitted to work with only the parts it was “fitted” to.

This problem has been discussed in many books (insert link to articles).

This page is a “work in progress”. Please excuse the sporadic content at times. Real world… real people…